DG2XZS Series Pressure Transmitter For Injection Molding Machine – Maxonic

DG2XZS Series Pressure Transmitter For Injection Molding Machine – Maxonic Detail:

DG2XZS series pressure transmitter is especially designed for injection molding machine, metal balers, metal forming machines, and it can also be used in some other machinery manufacturing industries. This kind of transmitter also uses MEMS Bicrystal silicon and ntegrated structure of 17-4PH stainless steel measuring diaphragm, thus ensuring its high stability and high precision. The core technology is that the measuring diaphragm and the process interface are integrally processed with a precision machine tool. At the same time, with leading circuit digital protection and temperature&pressure compensation technology, the pressure change is converted into a current or voltage signal. The product is small in size, easy to install, and uses a stainless steel shell to isolate and prevent corrosion.What’s more,its protection class is IP67.

1. Injection molding machine, metal balers, metal forming machines.

2. Machinery manufacturing industry and shipbuilding Industry.

3. Measurement and control technology.

4. Hydraulics and pneumatics system (Pumps and compressors).

1. Double overload integrated structure design, high overload capacity, burst pressure greater than 5 times full scale.

2. Suitable for power pressure of injection molding machine standard system, high pressure clamping pressure, pressure monitoring of injection pedestal inlet pressure.

3. Reverse protection, short circuit protection, surge protection.

4. The circuit meets intrinsic safety standards and is EMC certified with vibration resistance up to 20g.

5. USA ANSI Pressure Standards testing organization passed the test,and verified that the number of full-scale pressure cycles is greater than 10 million.

|

Performance Parameters |

Regular Measuring Range(Psi): |

3500 |

Response Time: |

<2ms |

| Other Industry Range(Psi): | 150,250,500,1000,1500,3000, 5000,7500,10000(Range can be customized) |

Vibration Resistance: |

20g (10Hz~2kHz) |

|

|

Overload Pressure: |

200%F.S. |

Impact Resistance: |

100g/11ms |

|

|

Burst Pressure: |

>500%F.S. |

Protection Class: |

IP67 |

|

|

Output Signal: |

4~20mA(two-wire),0~10V(three-wire) |

Service Life: |

10 Million Pressure Cycle Loading |

|

|

Supply Voltage: |

10~30V(4~20mA),12~30V(0~10V) |

Storage Temperature: |

-40~125℃ |

|

|

Load Resistance R: |

R(Ω)<(Us-10)/0.02(4~20mA) R(Ω)>2000 (0~10V) |

Operating Temperature: |

-20~85℃ Standard -40~125℃ Optional |

|

|

Current Consumption: |

Working current,Max24mA(4~20mA) Current Consumption<10mA(0~10V) |

Insulation Resistance: |

≥50MΏ(250V DC) |

|

|

Accuracy : |

0.5%F.S.Standard 0.25%F.S.Optional |

Process Connection: |

Gl/4E、1/2NPT and others |

|

|

Hysteresis:: |

<0.15%F.S. |

Electrical Connections: |

HSM Plug DIN43650A |

|

|

Nonlinearity : |

<0.15‰F.S. |

Cable Protection: |

Reverse polarity protection and short circuit protection |

|

|

Repeatability Error: |

<0.1%F.S. |

Wetted Material : |

17-4PH |

|

|

Temperature Effect On Zero Balance: |

0.25%F.S./10℃ |

Cover Material: |

304 Stainless steel |

|

|

Temperature Effect On Sensitivity: |

0.25%F.S./10℃ |

Long Term Stability: |

<0.1%F.S. |

|

|

Temperature Hysteresis: |

<0.1%F.S. |

|

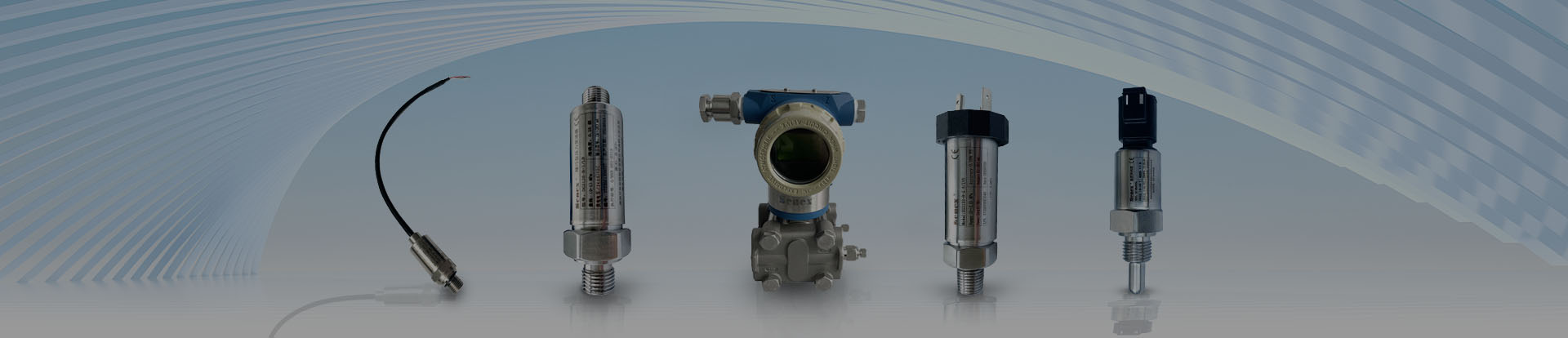

Product detail pictures:

Related Product Guide:

With reliable quality process, good reputation and perfect customer service, the series of products produced by our company are exported to many countries and regions for DG2XZS Series Pressure Transmitter For Injection Molding Machine – Maxonic , The product will supply to all over the world, such as: Sweden, Stuttgart, Guinea, We have advanced production technology, and pursuit innovative in products. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you must be willing to become partners with us. Looking forward to your inquiry.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.