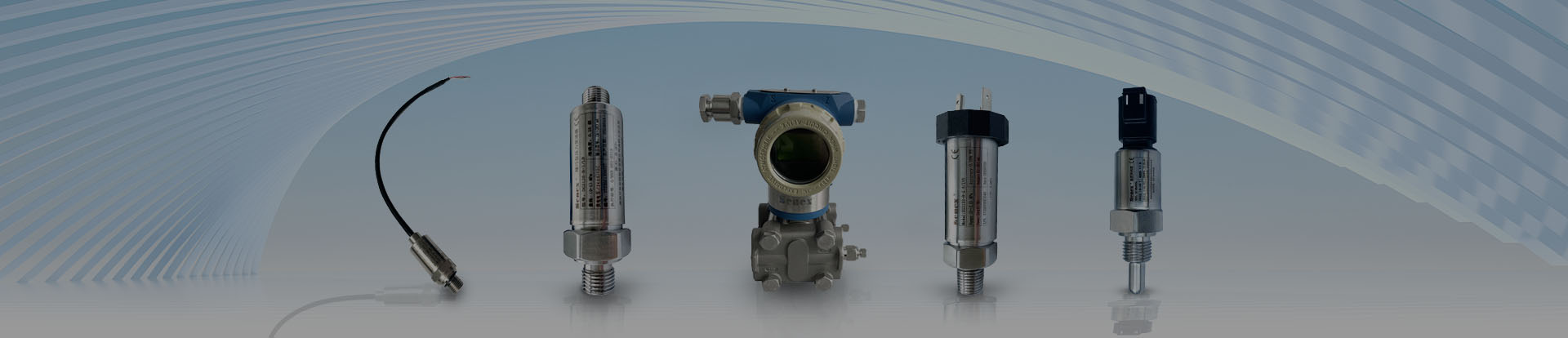

Fast delivery Piezoresistive Pressure Transmitter - DG2 Hydraulic Pressure Transmitter – Maxonic

Fast delivery Piezoresistive Pressure Transmitter - DG2 Hydraulic Pressure Transmitter – Maxonic Detail:

DG2 series hydraulic pressure transmitters are manufactured on a large scale by using MEMS Bicrystal technology and digital compensation amplifier circuits. In the temperature range of -40~125℃, after digital temperature compensation, its temperature drift characteristics can meet the needs of most industrial applications. There is no welding seam and sealing ring according to the overall design of process connection and integration.These designs ensure the reliability and long-term stability of the product, so that this type of transmitter has good adaptability to pulsating voltage and overload pressure.

1. Hydraulic and pneumatic control systems

2. Liquid level measurement and control

3. Petrochemical industry, environmental protection industry, air compression

4. Power station operation inspection, locomotive braking system

5. Thermal power unit

6. Light industry, machinery, metallurgy

7. Building automation, constant pressure water supply

8. Industrial process detection and control

1. The core technology adopts MEMS Bicrystal silicate packaging technology

2. Small size, high stability, high sensitivity

3. Anti-lightning, anti-RF interference

4. Can withstand 5 times the range of breaking pressure

5. Integrated metal structure

| Measuring Medium | Various liquids, gases or steam compatible with 17-4PH/316L stainless steel |

| Measuring Range(Psi) | 0~100,0~500,0~1000,0~1500,0~,3000,0~5000,0~10000 0~15000,0~20000(Range can be customized) |

| Overload Pressure | 3 times full scale |

| Output Signal | 4〜20mADC(two-wire), 0〜5VDC, 1 〜5VDC, 0. 5~4.5VDC (three-wire) RS485 I2C |

| Supply Voltage | 10〜30VDC |

| Medium Temperature | -40〜+125°C |

| Ambient Temperature | -40〜+125°C |

| Storage Temperature | -40〜+125°C |

| Relative Humidity | ≤95% (40°C) |

| Accuracy | (Non-Linearity, Hysteresis & Repeatability) 1%, 0.5%, 0.25%, 0.1%, 0.05% |

| Temperature Effect | ≤±0. 05%FS / °C (Temperature span-20〜+85°C,temperature effects including zero and span) |

| Temperature Compensation Span | -40〜85 °C |

| Stability | ±0. 15%FS/Year (Typical value) |

| Media Touching Material | 17-4PH/316L Stainless steel |

| Cover Material | 304 or 316 Stainless steel |

| Installation method | Threaded installation |

| Electrical Connections | Four-core shielded cable (protection grade IP68), HSM connector, M12* 1 connector (optional) |

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Fast delivery Piezoresistive Pressure Transmitter - DG2 Hydraulic Pressure Transmitter – Maxonic , The product will supply to all over the world, such as: Mongolia, New Zealand, Czech, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!