Characteristics of piezoresistive pressure sensor

Piezoresistive pressure sensor refers to the sensor made by using the piezoresistive effect of monocrystalline silicon material and integrated circuit technology. When the monocrystalline silicon material is subjected to the force, the resistivity changes, and the electrical signal output proportional to the force change can be obtained by measuring the circuit. It is also known as the diffused silicon piezoresistive pressure sensor, which is different from the adhesive strain gauge that needs to feel the external force indirectly through the elastic sensitive element, but directly through the silicon diaphragm to feel the measured pressure. 1. High sensitivity: the sensitivity factor of silicon strain resistance is 50 to 100 times higher than that of metal strain gauge, so the corresponding sensor sensitivity is very high, and the general full-scale output is about 100mv. Therefore, there is no special requirement for the interface circuit, and the application cost is correspondingly low. Because it is a non-mechanical structure sensor, it has a very high resolution, which is called unlimited abroad, that is, it is mainly limited by the external detection and reading instrument restrictions and noise interference restrictions, and generally can reach less than one hundred thousand of the full scale of the sensor. The silicon piezoresistive sensor has no dead zone in the low range near zero point and has good linearity. 2. High accuracy: Due to the feeling of the solid piezoresistive pressure sensor, the sensitive conversion and detection three parts are realized by the same component, there is no intermediate conversion link, so the non-repeatability and hysteresis error are minimal. At the same time, because the silicon single crystal itself has large stiffness and small deformation, it ensures good linearity, so the comprehensive static accuracy is high. 3. Small size, light weight, high dynamic frequency response: Because the core adopts an integrated process and has no transmission parts, it is small in size and light in weight. The small size chip coupled with the very high elastic modulus of silicon, the natural frequency of the sensitive element is very high. In the dynamic application, the dynamic accuracy is high, the use of wide frequency band, reasonable choice of design sensor appearance, the use of bandwidth can be from zero frequency to 100 KHZ. 4. Stable performance and high reliability: Because the working elastic deformation is as low as the order of micro-strain, the maximum displacement of the elastic film is in the order of sub-micron, so there is no wear, no fatigue, no aging. Life up to 107 pressure cycles or more. 5. Small temperature coefficient: due to the progress of microelectronics technology, the consistency of the four strain resistors can be very high, coupled with the progress of laser repair technology and computer automatic compensation technology, the zero position and sensitivity temperature coefficient of the silicon piezoresistive sensor has reached 10-5/℃ order of magnitude, that is, in the field of pressure sensors has exceeded the level of strain sensors with small temperature coefficients. 6. Wide adaptation medium: due to the excellent chemical corrosion resistance of silicon and good compatibility with silicone oil, the isolated structure is easy to achieve, even if the non-isolated piezoresistive pressure sensor has a considerable degree of ability to adapt to various media. 7. Safety and explosion-proof: Due to its low voltage, low current low power characteristics, it is intrinsically safe and explosion-proof products, can be widely used in various chemical industry detection and control fields, with the best cost performance.

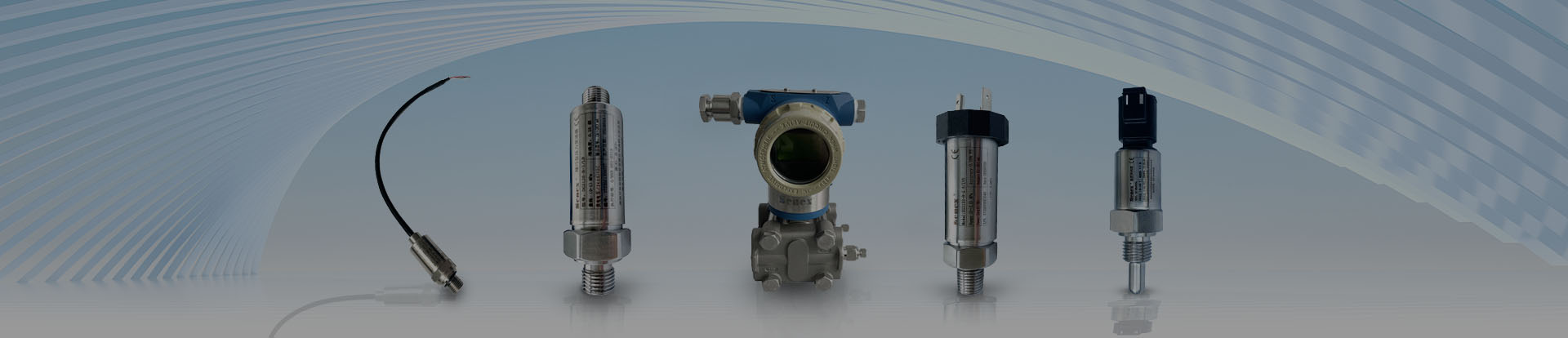

Related products

Post time: Sep-15-2023