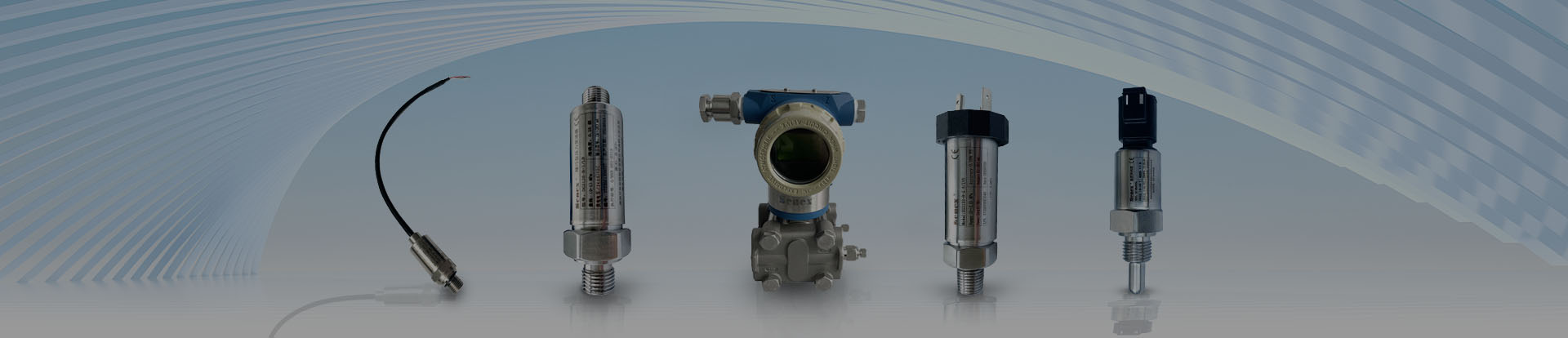

OEM/ODM Supplier Monocrystalline Silicon Pressure Sensor - DP1300-M Series Gauge or Absolute Pressure Transmitters – Maxonic

OEM/ODM Supplier Monocrystalline Silicon Pressure Sensor - DP1300-M Series Gauge or Absolute Pressure Transmitters – Maxonic Detail:

DP1300-M gauge pressure/absolute pressure transmitter has a wide range of applications, including petroleum, chemical, gas, electricity, military, water conservancy, food and etc.

1. Independent innovation and anti-overload structure make the transmitter more secure.

2. Unique dual sensor technology, accurate and stable measurement.

3. This kind of monosilicon type smart transmitter has excellent insulation performance between the core components and the shell, which ensures that the sensor output signal will not be disturbed on site.

| Standard Specification | Span adjustment based on standard zero point, with stainless steel 316 L diaphragm, filling liquid is silicone oil. | |||||||||||

| Performance Specification | Reference Accuracy of Adjustment Span | (Includes linearity from zero, hysteresis and repeatability): ± 0.075% | ||||||||||

| TD> 10 ( TD=Maximum span/adjustment span): ±(0.0075×TD)% | ||||||||||||

| Square root output accuracy is 1.5 times the linear reference accuracy above | ||||||||||||

| Ambient Temperature Effect | Span Code | - 20℃~65℃ Total impact | ||||||||||

| B/L | ±( 0.30×TD+ 0.20 )% ×Span | |||||||||||

| Other | ±( 0.20×TD+ 0.10 )% ×Span | |||||||||||

| Span Code | - 40℃~- 20℃ and 65℃~85℃ Total impact | |||||||||||

| B/L | ±( 0.30×TD+ 0.20 )% ×Span | |||||||||||

| Other | ±( 0.20×TD+ 0.10 )% ×Span | |||||||||||

| Over-span Effect | ±0 . 075% ×Span | |||||||||||

| Span Code | Amount of Influence | |||||||||||

| Long Term Stability | B/L | ±0.2% ×Span/ 1Year | ||||||||||

| Other | ±0.1% ×Span/ 1Year | |||||||||||

| Power Impact | ±0.001% / 10 V(12~42 V DC) | |||||||||||

| Measuring Range(Gauge pressure transmitter) | kpa/ mbar | kpa/ mbar | ||||||||||

| B | 0.6~6 /- 6~6 | 6 ~ 60 /- 60 ~ 60 | ||||||||||

| C | 2 ~ 40 /- 40 ~ 40 | 0.02 ~ 0.4 /- 0.4 ~ 0.4 | ||||||||||

| D | 2.5 ~ 250 /- 100 ~ 250 | 0.025 ~ 2.5 /- 1 ~ 2.5 | ||||||||||

| F | 30 ~ 3000 /- 100 ~ 3000 | 0.3 ~ 30 /- 1 ~ 30 | ||||||||||

| G | 100 ~ 10000 /- 1000 ~ 100000 | 1 ~ 100 /- 1 ~ 100 | ||||||||||

| H | 210 ~ 21000/-1000 ~ 210000 | 2.1 ~ 210 /- 1 ~ 210 | ||||||||||

| I | 400 ~ 40000 /-1000 ~ 400000 | 4 ~ 400 /- 1 ~ 400 | ||||||||||

| J | 600 ~ 60000 /-1000 ~ 600000 | 6 ~ 600 /- 1 ~ 60 | ||||||||||

| Measuring Range(Absolute pressure transmitter) | kpa/ mbar | kpa/ mbar | ||||||||||

| L | 2 ~ 40 /- 40 ~ 40 | 0.02 ~ 0.4 /- 0.4 ~ 0.4 | ||||||||||

| M | 2 . 5 ~ 250 /- 100 ~ 250 | 0.025 ~ 2.5 /- 1 ~ 2.5 | ||||||||||

| O | 30 ~ 3000 /- 100 ~ 3000 | 0.3 ~ 30 /- 1 ~ 30 | ||||||||||

| Span Limit | Within the upper and lower limits of the span, it can be adjusted arbitrarily; It is recommended to select a span code with the lowest possible turndown ratio to optimize performance characteristics. |

|||||||||||

| Zero Point Setting | Zero point and span can be adjusted to any value within the measurement span in the table (as long as: calibration span ≥ minimum span). | |||||||||||

| Installation Location Influence | The change of the installation position parallel to the diaphragm surface will not cause zero drift effect. If the change of the installation position and the diaphragm surface exceeds 90°, the zero position effect in the span of < 0.06 Psi will occur, which can be corrected by adjusting the zero adjustment, with no range effect. | |||||||||||

| Output | Two-wire, 4~20 m ADC, HART output digital communication can be selected, linear or square root output can also be selected. Output signal limit:Imin= 3.9 m A, Imax= 20.5 m A |

|||||||||||

| Alarm Current | Low report mode(Mini): 3.7 m A High report mode (Max): 21 m A Non-reporting mode (hold): keep the effective current value before the fault and report Standard setting of alarm current: high mode |

|||||||||||

| Response Time | The damping constant of the amplifier part is 0.1 s and the sensor time constant is 0.1 to 1.6 s, depending on the range and range ratio.The additional adjustable time constant is 0.1 to 60 s. | |||||||||||

| Preheat Time | < 15 s | |||||||||||

| Ambient Temperature | - 40~85℃ With LCD display and fluororubber sealing ring: – 20~65℃ |

|||||||||||

| Storage Temperature | - 50~85℃ With LCD display: – 40~85℃ |

|||||||||||

| Pressure Limit | From vacuum to maximum range | |||||||||||

| Material | Diaphragm: Stainless Steel 316 L, C-276 alloy Process Connection: Stainless Steel 316L Transmitter Cover: Aluminum alloy material, epoxy resin sprayed on the surface Filling Fluid: Silicone Oil |

|||||||||||

| Protection Class | IP67 | |||||||||||

Product detail pictures:

Related Product Guide:

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for OEM/ODM Supplier Monocrystalline Silicon Pressure Sensor - DP1300-M Series Gauge or Absolute Pressure Transmitters – Maxonic , The product will supply to all over the world, such as: Gambia, United Kingdom, Istanbul, After years of development, we have formed strong ability in new product development and strict quality control system to ensure excellent quality and service. With the support of many long term cooperated customers, our products are welcomed all over the world.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

Write your message here and send it to us